How should you test the tractor semitrailer connection for security – In the realm of transportation safety, ensuring the security of tractor-semitrailer connections is paramount. This article delves into the essential procedures and best practices for testing these connections, providing a comprehensive guide for maintaining optimal safety standards.

Through a thorough understanding of the connection components, visual inspection techniques, functional testing protocols, and safety measures, we aim to empower individuals with the knowledge and skills necessary to safeguard against potential hazards.

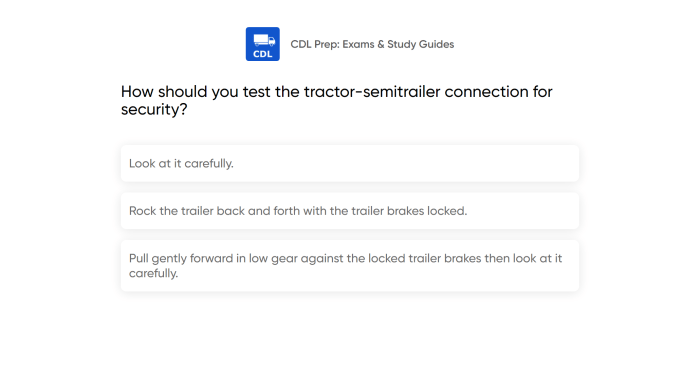

How Should You Test the Tractor Semitrailer Connection for Security

Tractor-Semitrailer Connection Components, How should you test the tractor semitrailer connection for security

The tractor-semitrailer connection is a critical aspect of ensuring the safe and secure operation of heavy vehicles. The connection involves several key components, including the fifth wheel, kingpin, and locking mechanisms. The fifth wheel is a large, horseshoe-shaped device mounted on the rear of the tractor.

It engages with the kingpin, a vertical pin located on the front of the semitrailer. The locking mechanisms secure the connection between the fifth wheel and kingpin, preventing the semitrailer from detaching from the tractor.

Visual Inspection

Before coupling the tractor and semitrailer, it is essential to conduct a thorough visual inspection of the connection components. This inspection should include checking for wear, damage, or any signs of compromise. The fifth wheel should be inspected for cracks, deformation, or excessive wear.

The kingpin should be checked for bending, damage to the locking mechanism, or any signs of corrosion. Any visible damage or wear should be addressed before coupling the vehicles.

Functional Testing

In addition to a visual inspection, functional testing should be performed to verify the proper operation of the connection. This testing includes checking the fifth wheel release mechanism, kingpin engagement, and locking system operation. The fifth wheel release mechanism should be tested to ensure that it can be easily and safely operated.

The kingpin engagement should be checked to ensure that the kingpin is properly seated in the fifth wheel and the locking system is engaged. The locking system should be tested to ensure that it can securely hold the connection under various operating conditions.

Safety Protocols

When testing the tractor-semitrailer connection, it is important to follow proper safety protocols to ensure the safety of personnel and equipment. These protocols include wearing appropriate personal protective equipment, such as gloves and safety glasses. It is also important to ensure that the vehicles are parked on a level surface and that the parking brake is engaged.

The testing area should be clear of any obstacles or hazards.

Documentation and Record-Keeping

Proper documentation and record-keeping of connection testing results are essential for ensuring the safety and compliance of heavy vehicle operations. The documentation should include the date and time of the test, the results of the visual inspection and functional testing, and any repairs or maintenance performed.

This documentation should be kept on file for future reference and to demonstrate compliance with industry standards and regulations.

Troubleshooting

During connection testing, various issues may arise. These issues can include problems with the fifth wheel release mechanism, kingpin engagement, or locking system operation. If any issues are encountered, it is important to troubleshoot the problem and resolve it before operating the vehicles.

Troubleshooting may involve inspecting the components for damage or wear, cleaning and lubricating the components, or adjusting the settings. If the problem cannot be resolved, it is recommended to seek assistance from a qualified mechanic.

Best Practices

To ensure the security of tractor-semitrailer connections, it is important to follow industry best practices. These best practices include regular testing and maintenance of the connection components, training and certification of personnel responsible for testing and operating the vehicles, and compliance with industry standards and regulations.

By following these best practices, organizations can help to prevent accidents and ensure the safe operation of heavy vehicles.

Legal and Regulatory Considerations

In many jurisdictions, there are legal and regulatory requirements related to tractor-semitrailer connection testing. These requirements may vary depending on the jurisdiction, but they typically include minimum standards for testing frequency, maintenance, and documentation. It is important for organizations to be aware of the legal and regulatory requirements in their jurisdiction and to ensure that they are met.

Failure to comply with these requirements can result in fines or other penalties.

Training and Certification

Personnel responsible for testing and operating tractor-semitrailers should be properly trained and certified. This training should cover the proper procedures for testing and operating the vehicles, as well as the safety protocols that must be followed. Certification programs are available through various organizations, and they provide a way to demonstrate that personnel have the necessary knowledge and skills to perform their jobs safely and effectively.

FAQ Explained

What are the key components of a tractor-semitrailer connection?

The fifth wheel, kingpin, and locking mechanisms are the essential components that ensure a secure connection between the tractor and semitrailer.

Why is visual inspection crucial before coupling?

Visual inspection allows for the detection of any wear, damage, or signs of compromise that could affect the connection’s integrity.

What are the steps involved in functional testing of the connection?

Functional testing includes checking the fifth wheel release mechanism, kingpin engagement, and locking system operation to ensure proper functionality.

What safety protocols should be followed during testing?

Safety protocols include wearing appropriate safety gear, using proper lifting equipment, and maintaining a safe working environment to prevent accidents.