Alcohol in air brake system – Unveiling the intricate relationship between alcohol and air brake systems, this exploration delves into the consequences, detection methods, and preventive measures surrounding alcohol contamination. Brace yourself for a comprehensive journey that will illuminate the critical role of maintaining alcohol-free air brake systems for enhanced safety and regulatory compliance.

Impact of Alcohol on Air Brake System Components

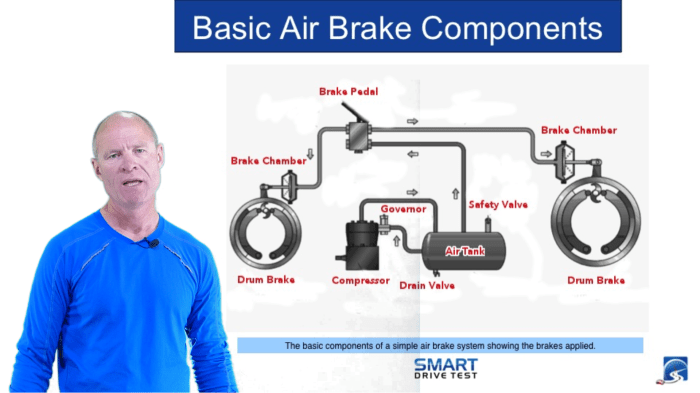

Alcohol, when present in an air brake system, can have detrimental effects on its components, leading to reduced braking efficiency and increased maintenance costs.

Alcohol can damage or impair various components within the air brake system, including seals, diaphragms, and valves.

Seals

- Alcohol can cause seals to swell, harden, or become brittle, compromising their ability to create a tight seal.

- Damaged seals can lead to air leaks, reduced system pressure, and impaired braking performance.

Diaphragms

- Alcohol can weaken or damage diaphragms, which are flexible membranes that separate air chambers.

- Compromised diaphragms can result in reduced air volume, decreased system pressure, and inefficient braking.

Valves

- Alcohol can corrode or clog valves, hindering their proper operation.

- Malfunctioning valves can cause air leaks, pressure imbalances, and reduced braking effectiveness.

Effects of Alcohol on Air Brake System Operation

Alcohol consumption can significantly impair the performance of air brake systems, compromising vehicle safety and compliance with regulations. Understanding these effects is crucial for drivers, fleet operators, and enforcement agencies.

Response Time

Alcohol impairs cognitive function and reaction time. When intoxicated, drivers may experience delayed response times to brake pedal inputs, leading to increased stopping distances and reduced ability to avoid collisions.

Braking Distance

Alcohol affects coordination and muscle control, making it harder for drivers to apply sufficient force to the brake pedal. This results in longer braking distances, reducing the vehicle’s ability to stop in time and increasing the risk of accidents.

Modulation

Modulation refers to the driver’s ability to control the amount of braking force applied. Alcohol impairs fine motor skills, making it difficult for drivers to modulate brake pressure smoothly. This can lead to sudden stops or over-braking, increasing the risk of skidding and loss of control.

Detection and Mitigation of Alcohol in Air Brake Systems

Alcohol contamination in air brake systems poses a significant threat to vehicle safety. Detecting and mitigating the presence of alcohol is crucial to prevent potential failures and accidents.

Alcohol Detection Methods

Various methods are employed to detect alcohol in air brake systems:

- Sensor Technologies:Sensors utilizing electrochemical or optical principles can detect alcohol vapor in the air brake system.

- Field Testing Procedures:Field test kits based on chemical reactions can provide qualitative or quantitative estimates of alcohol concentration.

Alcohol Mitigation Strategies

Once alcohol contamination is detected, strategies are implemented to mitigate its effects:

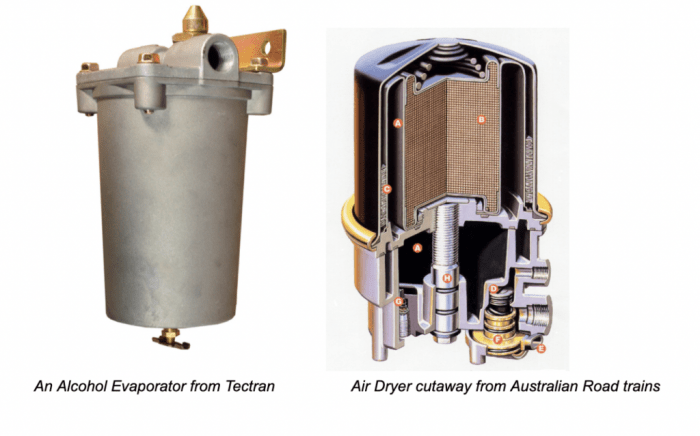

Alcohol Removal Devices

These devices, such as alcohol traps or filters, are installed in the air brake system to absorb and remove alcohol vapor from the compressed air.

System Maintenance Practices

Regular maintenance and inspections can help prevent alcohol contamination:

- Air Compressor Inspection:Inspecting air compressors for signs of coolant leaks can prevent coolant (which contains alcohol) from entering the air brake system.

- System Purging:Regularly purging the air brake system with clean, dry air helps remove any accumulated alcohol vapor.

Regulations and Compliance

The presence of alcohol in air brake systems is strictly prohibited due to its detrimental effects on system operation and safety. Various regulations and industry standards have been established to ensure compliance and prevent the use of alcohol in these systems.

Overview of Regulations and Standards

The Federal Motor Carrier Safety Administration (FMCSA) has implemented regulations under the Code of Federal Regulations (CFR) that prohibit the presence of alcohol in air brake systems. These regulations specify that alcohol must not be present in any part of the air brake system, including the compressor, reservoir, lines, valves, and brake chambers.

Alcohol in air brake systems can lead to component failure and even catastrophic accidents. It’s essential to understand the risks and take precautions to prevent alcohol from entering the system. For a moment of musical respite, immerse yourself in the intricate melodies of Veracini’s Sonata in E Minor . Its haunting harmonies and rhythmic complexities will transport you to a realm of pure sonic beauty.

Returning to the topic at hand, vigilance in preventing alcohol contamination in air brake systems ensures the safety and reliability of our vehicles.

Additionally, the Department of Transportation (DOT) has established guidelines for the inspection and maintenance of air brake systems, which include provisions for detecting and mitigating alcohol contamination.

Consequences of Non-Compliance

Non-compliance with regulations and standards related to alcohol in air brake systems can result in severe consequences, including:

Fines

Substantial fines may be imposed on carriers and drivers found to be in violation.

Vehicle Impoundment

Vehicles with contaminated air brake systems may be impounded until the problem is rectified.

Safety Violations

The presence of alcohol in air brake systems constitutes a safety violation and can lead to accidents and injuries.

Legal Liability

Carriers and drivers may be held legally liable for damages or injuries resulting from the use of alcohol in air brake systems.

Best Practices for Alcohol Prevention and Management

Alcohol contamination in air brake systems poses significant safety risks. Implementing comprehensive best practices is crucial to prevent and manage this issue effectively.

Effective prevention measures include establishing training programs to educate operators and fleet managers about the hazards of alcohol contamination, proper maintenance protocols to ensure system integrity, and appropriate storage procedures to prevent exposure to alcohol vapors.

Role of Operators and Fleet Managers, Alcohol in air brake system

Operators and fleet managers play vital roles in ensuring compliance with alcohol prevention measures and minimizing associated risks. Operators should be trained to recognize and report any signs of alcohol contamination, while fleet managers must implement robust maintenance and inspection programs to detect and address potential issues promptly.

Q&A: Alcohol In Air Brake System

What are the primary consequences of alcohol contamination in air brake systems?

Alcohol can damage seals, diaphragms, and valves, impairing system performance, reducing braking efficiency, and increasing maintenance costs.

How can alcohol affect the operation of air brake systems?

Alcohol can delay response time, extend braking distance, and hinder modulation, compromising vehicle safety and regulatory compliance.

What methods are used to detect alcohol in air brake systems?

Sensor technologies and field testing procedures can effectively identify alcohol contamination.

What are some best practices for preventing alcohol contamination in air brake systems?

Training programs, maintenance protocols, and proper storage procedures are crucial for preventing alcohol contamination.